Analog Clock Food on a Kitchen Scale Clip Art Measurement

Set up of residue scales, with weights

Scales used to measure out the weight of fruit in a supermarket

Weighing calibration for a baby includes a ruler for height measurement

A calibration or balance is a device used to mensurate weight or mass. These are also known as mass scales, weight scales, mass balances, and weight balances.

The traditional calibration consists of two plates or bowls suspended at equal distances from a fulcrum. I plate holds an object of unknown mass (or weight), while known masses are added to the other plate until static equilibrium is achieved and the plates level off, which happens when the masses on the two plates are equal. The perfect scale rests at neutral. A leap calibration volition make use of a spring of known stiffness to determine mass (or weight). Suspending a certain mass will extend the spring by a certain corporeality depending on the spring'due south stiffness (or leap constant). The heavier the object, the more than the spring stretches, every bit described in Hooke'due south law. Other types of scales making utilize of dissimilar physical principles also be.

Some scales tin be calibrated to read in units of strength (weight) such equally newtons instead of units of mass such as kilograms. Scales and balances are widely used in commerce, as many products are sold and packaged by mass.

Pan balance [edit]

History [edit]

The residuum scale is such a simple device that its usage likely far predates the show. What has allowed archaeologists to link artifacts to weighing scales are the stones for determining absolute mass. The balance scale itself was probably used to decide relative mass long before absolute mass.[1]

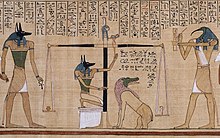

The oldest attested evidence for the existence of weighing scales dates to the Quaternary Dynasty of Egypt, with Deben (unit of measurement) rest weights, from the reign of Sneferu (c. 2600 BC) excavated, though earlier usage has been proposed.[ii] Carved stones bearing marks denoting mass and the Egyptian hieroglyphic symbol for gold have been discovered, which suggests that Egyptian merchants had been using an established system of mass measurement to catalog gilt shipments or golden mine yields. Although no actual scales from this era have survived, many sets of weighing stones as well as murals depicting the use of residuum scales suggest widespread usage.[iii]

Examples, dating c. 2400–1800 BC, have too been found in the Indus River valley. Uniform, polished rock cubes discovered in early settlements were probably used as mass-setting stones in residual scales. Although the cubes behave no markings, their masses are multiples of a common denominator. The cubes are fabricated of many dissimilar kinds of stones with varying densities. Clearly their mass, non their size or other characteristics, was a factor in sculpting these cubes.[3]

In China, the primeval weighing remainder excavated was from a tomb of the State of Chu of the Chinese Warring States Menstruum dating dorsum to the third to quaternary century BC in Mount Zuojiagong near Changsha, Hunan. The rest was fabricated of forest and used statuary masses.[iv] [5]

Variations on the remainder scale, including devices like the inexpensive and inaccurate bismar (unequal-armed scales),[6] began to see common usage by c. 400 B.C. by many small merchants and their customers. A plethora of calibration varieties each boasting advantages and improvements over one some other appear throughout recorded history, with such smashing inventors as Leonardo da Vinci lending a personal paw in their evolution.[7]

Even with all the advances in weighing scale design and development, all scales until the seventeenth century AD were variations on the balance calibration. The standardization of the weights used – and ensuring traders used the correct weights – was a considerable preoccupation of governments throughout this time.

-

-

Emperor Jahangir (reigned 1605–1627) weighing his son Shah Jahan on a weighing scale by artist Manohar (AD 1615, Mughal dynasty, Bharat).

Finely crafted pan residual or scales, with boxed ready of standardized gram masses

The original course of a balance consisted of a beam with a fulcrum at its center. For highest accurateness, the fulcrum would consist of a abrupt V-shaped pivot seated in a shallower V-shaped bearing. To decide the mass of the object, a combination of reference masses was hung on one finish of the beam while the object of unknown mass was hung on the other end (run across balance and steelyard balance). For loftier precision piece of work, such as empirical chemistry, the center beam residue is however one of the nigh authentic technologies available, and is commonly used for calibrating exam masses.

Notwithstanding, bronze fragments discovered in fundamental Germany and Italia had been used during the Bronze Age as an early class of currency.[8] In the same time flow, merchants had used standard weights of equivalent value betwixt viii and x.5 grams from Britain to Mesopotamia.[9]

Mechanical balances [edit]

The balance (also balance scale, beam balance and laboratory residual) was the first mass measuring musical instrument invented.[1] In its traditional form, it consists of a pivoted horizontal lever with arms of equal length – the axle – and a weighing pan[10] suspended from each arm (hence the plural name "scales " for a weighing instrument). The unknown mass is placed in one pan and standard masses are added to the other pan until the beam is as shut to equilibrium as possible. In precision balances, a more accurate determination of the mass is given by the position of a sliding mass moved along a graduated scale. Technically, a balance compares weight rather than mass, simply, in a given gravitational field (such as Earth'southward gravity), the weight of an object is proportional to its mass, so the standard masses used with balances are ordinarily labeled in units of mass (eastward.g. g or kg).

Market place hawker weighing meat (in catty) on a beam balance, Malaysia (1969)

Masses of fifty, 20, 1, two, v and ten grams

Unlike jump-based scales, balances are used for the precision measurement of mass every bit their accuracy is non affected by variations in the local gravitational field. (On Globe, for example, these can corporeality to ±0.five% betwixt locations.[11]) A modify in the strength of the gravitational field caused by moving the balance does non modify the measured mass, considering the moments of force on either side of the beam are affected equally. A residual will render an authentic measurement of mass at any location experiencing a constant gravity or dispatch.

Very precise measurements are achieved past ensuring that the balance'southward fulcrum is substantially friction-free (a pocketknife border is the traditional solution), by attaching a pointer to the beam which amplifies any deviation from a balance position; and finally by using the lever principle, which allows partial masses to be applied by move of a modest mass along the measuring arm of the beam, equally described above. For greatest accuracy, there needs to be an allowance for the buoyancy in air, whose effect depends on the densities of the masses involved.

Aluminum, mass-produced balance scale (steelyard balance) sold and used throughout Communist china: the scale tin can be inverted and held by the larger ring beneath the user's right hand to produce greater leverage for heavier loads (Hainan, Mainland china, 2011)

To reduce the demand for big reference masses, an off-center axle can be used. A balance with an off-center beam tin can be almost every bit authentic as a calibration with a center beam, only the off-center beam requires special reference masses and cannot exist intrinsically checked for accuracy by just swapping the contents of the pans as a center-beam balance tin can. To reduce the need for small graduated reference masses, a sliding weight chosen a poise can be installed and so that information technology tin be positioned along a calibrated scale. A poise adds further intricacies to the calibration process, since the exact mass of the poise must be adapted to the exact lever ratio of the axle.

For greater convenience in placing large and awkward loads, a platform can exist floated on a cantilever beam system which brings the proportional force to a noseiron bearing; this pulls on a stilyard rod to transmit the reduced strength to a conveniently sized beam.

One still sees this pattern in portable beam balances of 500 kg capacity which are unremarkably used in harsh environments without electricity, as well as in the lighter duty mechanical bathroom scale (which really uses a leap calibration, internally). The additional pivots and bearings all reduce the accuracy and complicate calibration; the bladder organisation must be corrected for corner errors before the span is corrected by adjusting the residual beam and poise.

A Roberval remainder. The pivots of the parallelogram understructure makes it insensitive to load positioning away from center, so improves its accuracy, and ease of utilise.

Roberval balance [edit]

In 1669 the Frenchman Gilles Personne de Roberval presented a new kind of balance calibration to the French Academy of Sciences. This scale consisted of a pair of vertical columns separated by a pair of equal-length artillery and pivoting in the center of each arm from a central vertical column, creating a parallelogram. From the side of each vertical column a peg extended. To the amazement of observers, no matter where Roberval hung two equal weight forth the peg, the scale nevertheless balanced. In this sense, the scale was revolutionary: it evolved into the more-unremarkably encountered form consisting of ii pans placed on vertical column located above the fulcrum and the parallelogram below them. The advantage of the Roberval design is that no matter where equal weights are placed in the pans, the scale will withal balance.

Further developments have included a "gear balance" in which the parallelogram is replaced past any odd number of interlocking gears greater than ane, with alternate gears of the aforementioned size and with the fundamental gear fixed to a stand and the outside gears fixed to pans, likewise as the "sprocket gear residuum" consisting of a bicycle-type chain looped effectually an odd number of sprockets with the central one stock-still and the outermost two complimentary to pivot and attached to a pan.

Because it has more moving joints which add together friction, the Roberval balance is consistently less authentic than the traditional beam balance, but for many purposes this is compensated for past its usability.

Torsion residue scale made by Torbal

Torsion remainder [edit]

The torsion rest is one of the most mechanically authentic and analog balances. Chemist's schools still teach how to utilize torsion balances in the U.S. It utilizes pans like a traditional remainder that lie on tiptop of a mechanical chamber which bases measurements on the amount of twisting of a wire or fiber inside the chamber. The calibration must nevertheless use a calibration weight to compare against, and tin counterbalance objects greater than 120 mg and come inside a margin of fault +/- 7 mg. Many microbalances and ultra-microbalances that weigh partial gram values are torsion balances. A common fiber type is quartz crystal.[12]

Electronic devices [edit]

Microbalance [edit]

A microbalance (also chosen an ultramicrobalance, or nanobalance) is an musical instrument capable of making precise measurements of the mass of objects of relatively small-scale mass: on the order of a million parts of a gram and below.

Analytical balance [edit]

Weighing balance, with precision of 0.one mg

An analytical residual is a class of balance designed to measure small mass in the sub-milligram range. The measuring pan of an analytical rest (0.ane mg or amend) is within a transparent enclosure with doors so that grit does not collect and then whatsoever air currents in the room do not bear upon the balance's operation. This enclosure is often called a draft shield. The employ of a mechanically vented balance safety enclosure, which has uniquely designed acrylic airfoils, allows a smoothen turbulence-complimentary airflow that prevents residuum fluctuation and the measure of mass downwardly to 1 μg without fluctuations or loss of production.[ citation needed ] Too, the sample must be at room temperature to prevent natural convection from forming air currents inside the enclosure from causing an error in reading. Single-pan mechanical commutation balances maintain consequent response throughout the useful capacity, which is accomplished past maintaining a constant load on the residuum beam and thus the fulcrum by subtracting mass on the aforementioned side of the beam to which the sample is added.[ citation needed ]

Electronic analytical scales measure the force needed to counter the mass being measured rather than using actual masses. As such they must accept calibration adjustments made to compensate for gravitational differences.[xiii] They use an electromagnet to generate a force to counter the sample existence measured and output the consequence past measuring the forcefulness needed to achieve balance. Such a measurement device is called an electromagnetic force restoration sensor.[14]

Pendulum balance scales [edit]

Pendulum type scales do not use springs. These designs utilize pendulums and operate equally a residual that is unaffected by differences in gravity. An example of application of this design are scales made by the Toledo Scale Company.[15]

Programmable scales [edit]

A programmable scale has a programmable logic controller in it, allowing it to be programmed for various applications such as batching, labeling, filling, truck scales, and more.

Symbolism [edit]

The scale pictured in the glaze of arms of Pöytyä

The scales (specifically, a 2-pan, axle balance) are one of the traditional symbols of justice, as wielded by statues of Lady Justice. This corresponds to the utilise in a metaphor of matters being "held in the remainder". It has its origins in ancient Arab republic of egypt.[ commendation needed ]

Scales are also the symbol for the astrological sign Libra.

Scales (specifically, a ii-pan, axle balance in a country of equal remainder) are the traditional symbol of Pyrrhonism indicating the equal residue of arguments used in inducing epoche.[16]

Force-measuring (weight) scales [edit]

History [edit]

A simple balance from the 19th century

Although records dating to the 1700s refer to spring scales for measuring mass, the earliest pattern for such a device dates to 1770 and credits Richard Salter, an early scale-maker.[3] Bound scales came into broad usage in the United Kingdom after 1840 when R. West. Winfield developed the candlestick calibration for weighing letters and packages, required subsequently the introduction of the Uniform Penny Post.[17] Postal workers could work more than quickly with spring scales than rest scales considering they could be read instantaneously and did not have to exist carefully counterbalanced with each measurement.

By the 1940s, various electronic devices were being fastened to these designs to make readings more accurate.[3] [7] Load cells – transducers that convert force to an electric signal – have their ancestry equally early every bit the late nineteenth century, simply information technology was not until the late twentieth century that their widespread usage became economically and technologically viable.[xviii]

Mechanical scales [edit]

A mechanical scale or balance is used to describe a weighing device that is used to measure the mass, force exertion, tension, and resistance of an object without the need of a power supply. Types of mechanical scales include leap scales, hanging scales, triple axle balances, and force gauges.

Jump scales [edit]

A spring scale measures mass by reporting the distance that a spring deflects under a load. This contrasts to a rest, which compares the torque on the arm due to a sample weight to the torque on the arm due to a standard reference mass using a horizontal lever. Spring scales measure force, which is the tension force of constraint acting on an object, opposing the local force of gravity.[19] They are usually calibrated and so that measured force translates to mass at earth's gravity. The object to exist weighed can exist but hung from the jump or assault a pivot and bearing platform.

In a spring calibration, the spring either stretches (every bit in a hanging scale in the produce department of a grocery store) or compresses (every bit in a unproblematic bathroom calibration). Past Hooke's constabulary, every spring has a proportionality constant that relates how hard it is pulled to how far it stretches. Weighing scales use a spring with a known spring constant (come across Hooke's law) and measure the displacement of the bound by whatever diverseness of mechanisms to produce an guess of the gravitational force applied past the object.[20] Rack and pinion mechanisms are often used to convert the linear spring motion to a dial reading.

Spring scales have 2 sources of mistake that balances do not: the measured mass varies with the forcefulness of the local gravitational force (by as much every bit 0.5% at different locations on Earth), and the elasticity of the measurement spring can vary slightly with temperature. With proper manufacturing and setup, withal, spring scales can be rated as legal for commerce. To remove the temperature error, a commerce-legal spring scale must either have temperature-compensated springs or be used at a fairly abiding temperature. To eliminate the result of gravity variations, a commerce-legal spring calibration must be calibrated where information technology is used.

Hydraulic or pneumatic scale [edit]

Information technology is also mutual in high-capacity applications such as crane scales to use hydraulic force to sense mass. The test force is applied to a piston or diaphragm and transmitted through hydraulic lines to a dial indicator based on a Bourdon tube or electronic sensor.[21]

Domestic Weighing Scale [edit]

A mechanical bath scale. Pressure level on the internal springs rotates a disc displaying the user's weight in pounds.

Electronic digital scales display weight as a number, usually on a liquid crystal brandish (LCD). They are versatile because they may perform calculations on the measurement and transmit information technology to other digital devices. On a digital scale, the force of the weight causes a spring to deform, and the amount of deformation is measured by one or more than transducers called strain gauges. A strain gauge is a conductor whose electrical resistance changes when its length changes. Strain gauges have limited chapters and larger digital scales may use a hydraulic transducer called a load cell instead. A voltage is applied to the device, and the weight causes the current through it to change. The current is converted to a digital number by an analog-to-digital converter, translated by digital logic to the correct units, and displayed on the display. Usually, the device is run by a microprocessor bit.

Digital bathroom calibration [edit]

A digital bathroom scale is a calibration on the floor which a person stands on. The weight is shown on an LED or LCD brandish. The digital electronics may do more than just display weight, it may calculate body fatty, BMI, lean mass, muscle mass, and water ratio. Some modern bathroom scales are wirelessly or cellularly connected and have features similar smartphone integration, cloud storage, and fettle tracking. They are usually powered by a push button prison cell, or battery of AA or AAA size.

Digital kitchen scale [edit]

Digital kitchen scales are used for weighing food in a kitchen during cooking. These are usually lightweight and meaty.

Strain gauge scale [edit]

In electronic versions of leap scales, the deflection of a beam supporting the unknown mass is measured using a strain estimate, which is a length-sensitive electrical resistance. The chapters of such devices is just limited past the resistance of the beam to deflection. The results from several supporting locations may be added electronically, and so this technique is suitable for determining the mass of very heavy objects, such as trucks and rail cars, and is used in a modern weighbridge.

Supermarket and other retail scale [edit]

These scales are used in the modern baker, grocery, delicatessen, seafood, meat, produce and other perishable goods departments. Supermarket scales tin print labels and receipts, mark mass and count, unit toll, total price and in some cases tare. Some modern supermarket scales print an RFID tag that tin be used to track the particular for tampering or returns. In most cases, these types of scales take a sealed calibration so that the reading on the display is right and cannot be tampered with. In the United states, the scales are certified by the National Type Evaluation Program (NTEP), in Southward Africa by the S African Bureau of Standards, in Commonwealth of australia, they are certified by the National Measurement Plant (NMI) and in the United kingdom of great britain and northern ireland by the International Organization of Legal Metrology.

Testing and certification [edit]

About countries regulate the design and servicing of scales used for commerce. This has tended to crusade scale engineering to lag backside other technologies considering expensive regulatory hurdles are involved in introducing new designs. Nevertheless, there has been[ when? ] a tendency to "digital load cells" which are actually strain-gauge cells with dedicated analog converters and networking built into the prison cell itself. Such designs accept reduced the service issues inherent with combining and transmitting a number of xx millivolt signals in hostile environments.

Government regulation generally requires periodic inspections past licensed technicians, using masses whose calibration is traceable to an canonical laboratory. Scales intended for non-trade use, such equally those used in bathrooms, doctor'southward offices, kitchens (portion control), and price interpretation (but not official price determination) may exist produced, but must by law exist labelled "Non Legal for Trade" to ensure that they are not re-purposed in a way that jeopardizes commercial involvement.[ citation needed ] In the United States, the certificate describing how scales must be designed, installed, and used for commercial purposes is NIST Handbook 44. Legal For Trade (LFT) certification ordinarily approve the readability as repeatability/ten to ensure a maximum margin of error of 10%.[ description needed ] [ citation needed ]

Considering gravity varies by over 0.v% over the surface of the earth, the stardom betwixt force due to gravity and mass is relevant for accurate scale of scales for commercial purposes. Usually, the goal is to measure the mass of the sample rather than its force due to gravity at that particular location.

Traditional mechanical residual-beam scales intrinsically measured mass. Only ordinary electronic scales intrinsically measure the gravitational strength between the sample and the world, i.e. the weight of the sample, which varies with location. So such a scale has to be re-calibrated after installation, for that specific location, in order to obtain an authentic indication of mass.

Sources of error [edit]

Some of the sources of fault in weighing are:

- Buoyancy – Objects in air develop a buoyancy forcefulness that is directly proportional to the volume of air displaced. The deviation in density of air due to barometric force per unit area and temperature creates errors.[22]

- Error in the mass of reference weight

- Air gusts, even small ones, which push button the scale up or down

- Friction in the moving components that causes the scale to attain equilibrium at a unlike configuration than a frictionless equilibrium should occur.

- Settling airborne dust contributing to the weight

- Mis-calibration over fourth dimension, due to migrate in the circuit'due south accuracy, or temperature change

- Mis-aligned mechanical components due to thermal expansion or contraction of components

- Magnetic fields interim on ferrous components

- Forces from electrostatic fields, for example, from feet shuffled on carpets on a dry out day

- Chemic reactivity between air and the substance beingness weighed (or the balance itself, in the form of corrosion)

- Condensation of atmospheric water on cold items

- Evaporation of water from wet items

- Convection of air from hot or cold items

- Gravitational differences for a scale which measures force, but not for a residuum.[23]

- Vibration and seismic disturbances

Hybrid bound and balance scales [edit]

A prototype of an elastic arm scale measuring a mass.

Rubberband arm scale [edit]

In 2014 a concept of hybrid calibration was introduced, the elastically deformable arm scale,[24] which is a combination between a spring calibration and a beam balance, exploiting simultaneously both principles of equilibrium and deformation. In this scale, the rigid artillery of a classical beam balance (for example a steelyard) are replaced with a flexible elastic rod in an inclined frictionless sliding sleeve. The rod can achieve a unique sliding equilibrium when two vertical dead loads (or masses) are applied at its edges. Equilibrium, which would be incommunicable with rigid artillery, is guaranteed considering configurational forces develop at the two edges of the sleeve as a consequence of both the free sliding condition and the nonlinear kinematics of the elastic rod. This mass measuring device can also piece of work without a counterweight.

Come across also [edit]

- Ampere rest

- Apparent weight

- Auncel

- Combination weigher

- Digital spoon scale

- Evans remainder

- Faraday balance

- Force gauge

- Gouy residue

- Kibble balance, as well known as a Watt residual

- Mass versus weight

- Multihead weigher

- Nutrition scale

- Roberval residuum

- Steelyard balance

- Tare weight

- Triple axle rest

- Truck scale

- Counterbalance business firm - historic public building for the weighing of goods

- Counterbalance lock - for weighing canal barges

- Weigh station, a checkpoint to inspect vehicular weights, normally equipped with a truck calibration (weigh bridge)

References [edit]

- ^ a b "Download – A Short History to Weighing: AWTX Museum Book". Averyweigh-tronix.com. Archived from the original on March 2, 2012. Retrieved 2015-03-05 .

- ^ Rahmstorf, Lorenz. "In Search of the Earliest Balance Weights, Scales and Weighing Systems from the East Mediterranean, the Near and Center Eastward".

- ^ a b c d Petruso, Karl M (1981). "Early Weights and Weighing in Egypt and the Indus Valley". M Bulletin. 79: 44–51. JSTOR 4171634.

- ^ Rossi, Cesare; Russo, Flavio; Russo, Ferruccio (2009). Ancient Engineers' Inventions: Precursors of the Present (History of Mechanism and Machine Scientific discipline) (published May eleven, 2009). p. 21. ISBN978-9048122523.

- ^ Yan, Hong-Sen (2007). Reconstruction Designs of Lost Ancient Chinese Machinery. Springer (published Nov eighteen, 2007). pp. 53–54.

- ^ "ISASC". ISASC. Retrieved 2014-02-26 .

- ^ a b "The History of Weighing". Averyweigh-tronix.com. 2012-03-02. Archived from the original on March 2, 2012. Retrieved 2014-03-05 .

- ^ Ialongo, Nicola; Lago, Giancarlo (2021). "A minor change revolution. Weight systems and the emergence of the get-go Pan-European money". Journal of Archaeological Science. 129: 105379. doi:10.1016/j.jas.2021.105379.

- ^ Ialongo, Nicola; Hermann, Raphael; Rahmstorf, Lorenz (2021). "Bronze Age weight systems as a measure of marketplace integration in Western Eurasia". PNAS. 118 (27): e2105873118. doi:10.1073/pnas.2105873118. PMC8271817. PMID 34183401.

- ^ Or "scale", "scalepan" or the obsolete "bowl" (A Practical Dictionary of the English language and German Languages (1869), p. 1069).

- ^ Hodgeman, Charles, Ed. (1961). Handbook of Chemical science and Physics, 44th Ed. Cleveland, United states of america: Chemical Safe Publishing Co. pp. 3480–3485.

- ^ "Types of Balances and Scales, Common Terms & Care - Grainger KnowHow".

- ^ "A&D training material" (PDF). Sandd.jp. Retrieved 2014-02-26 .

- ^ "Sensors Mag". Athenaeum.sensorsmag.com. Retrieved 2014-02-26 .

- ^ "Finding Aid : The Toledo Scale Collection" (PDF). Utoledo.edu. Retrieved 2014-02-26 .

- ^ Sarah Bakewell, How to Live: Or A Life of Montaigne in One Question and Twenty Attempts at an Answer 2011 p 127 ISBN 1590514831

- ^ Contumely, Brian (2006). "Candlesticks, Function ane" (PDF). Equilibrium (1): 3099–3109. Retrieved 2014-02-26 .

- ^ "Load Cells". Omega.com. Retrieved 2014-02-26 .

- ^ "A Guide to Choosing the Best Mechanical Scale - Inscale". Inscale Scales. Archived from the original on 2017-12-06. Retrieved 2017-12-06 .

- ^ "What is Hooke's Law?". Retrieved 2017-12-06 .

- ^ "A brief history of weights and measures" (PDF). California Department of Food and Agriculture Sectionalization of Measurement Standards.

- ^ "Applying air buoyancy corrections" (PDF). Andrew.ucsd.edu. September 29, 1997. Archived from the original (PDF) on September vii, 2006. Retrieved 2014-03-05 .

- ^ Davis, R.S.; Welch, B.E. (1988). "Practical Doubt Limits to the Mass Determination of a Piston-Gage Weight" (PDF). Journal of Enquiry of the National Bureau of Standards. 93 (4): 565–571. doi:x.6028/jres.093.149 . Retrieved 2014-02-26 .

- ^ Bosi, F.; Misseroni, D.; Dal Corso, F.; Bigoni, D. (2014). "An elastica arm calibration" (PDF). Proceedings of the Royal Lodge A: Mathematical, Physical and Engineering Sciences. 470 (2169): 20140232. arXiv:1509.06713. Bibcode:2014RSPSA.47040232B. doi:ten.1098/rspa.2014.0232. PMC4123770. PMID 25197248.

External links [edit]

- Airy, Wilfrid (1911). . In Chisholm, Hugh (ed.). Encyclopædia Britannica. Vol. 28 (11th ed.). Cambridge University Press. pp. 468–477. This a comprehensive review of the history and contemporaneous state of weighing machines.

- Chisholm, Hugh, ed. (1911). . Encyclopædia Britannica. Vol. iii (11th ed.). Cambridge Academy Press. pp. 234–235.

- National Conference on Weights and Measures, NIST Handbook 44, Specifications, Tolerances, And Other Technical Requirements for Weighing and Measuring Devices, 2003

- Analytical Balance commodity at ChemLab

- "The Precious Necklace Regarding Weigh Scales" is an 18th-century manuscript by Abd al-Rahman al-Jabarti nigh the "design and operation" of scales

- Modern Belittling Weighing Balance Article

Source: https://en.wikipedia.org/wiki/Weighing_scale

Post a Comment for "Analog Clock Food on a Kitchen Scale Clip Art Measurement"